How Robotics Will Transform Factories

Created on 28 December, 2025 • Tech Blog • 75 views • 10 minutes read

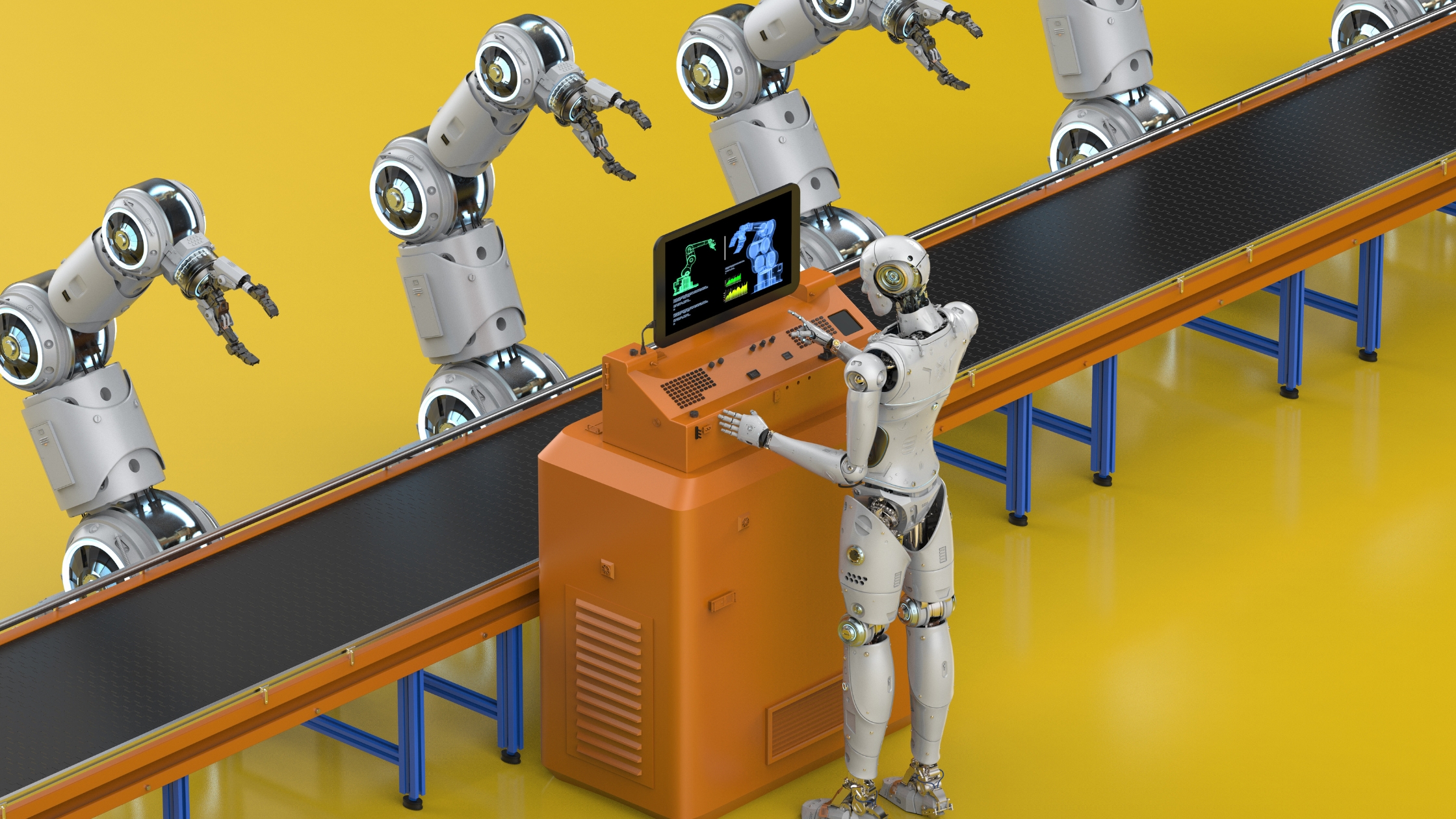

Explore how robotics will transform factories in 2026: From humanoid coworkers and Agentic AI to hyper-flexible manufacturing and lights-out shifts.

How Robotics Will Transform Factories: The 2026 Industrial Evolution

Table of Contents

- The 2026 Shift: From Automated Machines to Autonomous Coworkers

- Agentic AI: The Brain Powering the New Robotic Workforce

- The Rise of Humanoid Robots on the Factory Floor

- Cobots 2.0: Seamless Human-Robot Collaboration

- Hyper-Flexible Manufacturing and Software-Defined Factories

- Intralogistics: AMRs and the End of Bottlenecks

- Predictive Quality Control: Machine Vision and Edge Intelligence

- Sustainable Automation: Green Robotics and Circular Efficiency

- The Lights-Out Factory: 24/7 Autonomous Shifts

- Conclusion: The Future of the Human Industrial Worker

The 2026 Shift: From Automated Machines to Autonomous Coworkers

As we navigate through 2025 and look toward 2026, the industrial world is witnessing a fundamental change in the definition of "automation." For decades, robots in factories were rigid, caged, and programmed for a single repetitive task. Today, we are entering the era of "Physical AI." This transformation moves beyond the simple execution of code toward autonomous systems that can perceive, reason, and act within unstructured environments. By 2026, the industrial robotics market is expected to contribute nearly 65 percent of all factory automation growth, driven by a desperate need to solve chronic labor shortages and the global push for reshoring production.

In this new landscape, robots are no longer just tools; they are becoming autonomous coworkers. The "castle and moat" strategy of keeping robots behind safety fences is being dismantled in favor of integrated, software-defined environments. In 2026, the competitive advantage for manufacturers lies in "Hyper-Flexibility"—the ability to reconfigure an entire production line in hours rather than months. This shift is turning factories into dynamic organisms that can adapt to seasonal spikes, supply chain disruptions, and the growing consumer demand for personalized, small-batch products. The factory of the future is not just a place where things are made; it is an intelligent ecosystem where the boundary between hardware and software has effectively vanished.

Agentic AI: The Brain Powering the New Robotic Workforce

The most significant catalyst for the robotic revolution in 2026 is the integration of Agentic AI. Unlike traditional AI that merely analyzes data, Agentic AI takes action. In the context of a factory, this means AI "agents" that oversee complex industrial workflows end-to-end with minimal human interaction. These agents connect sensors, industrial machinery, and human resources into a unified command structure. Instead of a human operator manually adjusting a robotic arm's speed, the AI agent monitors real-time throughput data and autonomously optimizes the robot's movements to prevent bottlenecks.

This "Cognitive Industry" approach allows robots to learn from their mistakes. Using reinforcement learning and synthetic data, robots can "practice" a task in a digital twin environment millions of times before ever performing it on the physical floor. In 2026, we are seeing the emergence of Multi-Agent Orchestration, where different robotic systems—such as a mobile lifter and a stationary assembly arm—communicate with each other to solve problems. If a delivery robot is delayed, the assembly arm proactively adjusts its workflow or alerts a human supervisor. This level of self-management is moving us closer to the goal of "Zero-Downtime Culture," where the factory manages itself with unprecedented precision.

The Rise of Humanoid Robots on the Factory Floor

While specialized robotic arms remain the workhorses of industry, 2026 is the year humanoid robots move from experimental pilots to tangible commercialization. Leading the charge are companies like Boston Dynamics, with the new electric Atlas, and Tesla’s Optimus. The appeal of the humanoid form factor is simple: our factories were built by humans, for humans. A robot with legs, hands, and a human-like reach can navigate stairs, move through narrow aisles, and use the same tools that a human worker uses without requiring a total redesign of the factory infrastructure.

In late 2025, several tier-one automotive manufacturers began integrating humanoid assistants for "brownfield" logistics—tasks that involve moving parts between legacy machines that were never designed for automation. By 2026, these general-purpose assistants are being used for depalletizing, sorting, and even basic assembly. While full, high-speed humanoid deployment is still scaling, their presence on the shop floor signifies a move toward Generalized AI Robotics. Instead of buying a robot that only welds, manufacturers can now invest in a platform that can be "retrained" via software updates to handle dozens of different tasks as the factory's needs evolve.

Cobots 2.0: Seamless Human-Robot Collaboration

Collaborative robots, or "Cobots," have evolved significantly in 2026. They are no longer just "slow robots that stop when you touch them." The new generation of Cobots utilizes advanced Computer Vision and Liveness Detection to work alongside humans at full industrial speeds. By using high-fidelity sensors to create a "digital bubble" around themselves, these robots can anticipate a human's movement and adjust their path in milliseconds, maintaining both safety and high throughput. This allows for a "Side-by-Side" workflow where the robot handles the heavy lifting or high-precision tasks while the human focuses on quality oversight and complex problem-solving.

This "Human-Centric Automation" is the core of Industry 5.0. In 2026, Cobots are increasingly affordable for Small and Medium Enterprises (SMEs), allowing even local machine shops to compete with global giants. The ease of programming has also reached a breakthrough; using "Natural Language Programming," a worker can simply show the robot a task or explain it verbally, and the AI agent translates that into motion code. This democratization of robotics means that the person "programming" the robot is the skilled machinist on the floor, not a data scientist in an office, ensuring that tribal knowledge and craftsmanship remain at the heart of the manufacturing process.

Hyper-Flexible Manufacturing and Software-Defined Factories

The rigid, fixed assembly line is a relic of the 20th century. In 2026, the trend is toward Hyper-Flexible Manufacturing. This is powered by "Software-Defined Factories" (SDF) where the hardware is modular and the logic is centralized in the cloud or at the edge. If a manufacturer needs to switch from making Model A to Model B, they no longer need to spend weeks retooling. Instead, they push a software update that reconfigures the robotic cells, changes the paths of autonomous vehicles, and updates the machine vision parameters for quality control.

This flexibility is supported by Generative Design tools. In 2026, engineers are using AI to explore thousands of design iterations that prioritize "Robot-Friendliness." Parts are being designed to be 30% lighter and easier for a robotic gripper to handle, which in turn reduces the energy consumption and wear-and-tear on the robotic fleet. This tight integration between design and autonomous production is reducing product development cycles by up to 50 percent, allowing brands to react to market trends in real-time. In the world of 2026, the fastest factory—not the largest—is the one that wins.

Intralogistics: AMRs and the End of Bottlenecks

Internal material movement has long been the "silent killer" of factory efficiency. In 2026, Autonomous Mobile Robots (AMRs) have become the standard for intralogistics. Unlike older Automated Guided Vehicles (AGVs) that required magnetic strips or wires in the floor, modern AMRs use SLAM (Simultaneous Localization and Mapping) and AI to navigate dynamic environments. They can dodge forklifts, route around spills, and even communicate with elevators to move between different floors of a facility. By 2026, "Flow beats Speed" has become the mantra for plant managers.

The integration of AMRs with robotic arms—often called "Mobile Manipulators"—is creating a fully autonomous supply chain within the factory walls. These robots can drive to a bin, pick a part, and deliver it directly to an assembly station "just-in-time." This eliminates the need for large, cluttered WIP (Work-In-Process) buffer zones, freeing up valuable floor space for more production. As we move into 2026, we are also seeing the rise of Hybrid Navigation, where robots can seamlessly transition from indoor GPS to outdoor 5G-enabled navigation, allowing them to move materials between different buildings in a sprawling industrial complex without human intervention.

Predictive Quality Control: Machine Vision and Edge Intelligence

In 2026, quality control is no longer a step at the end of the line; it is an "always-on" robotic process. Machine Vision systems, powered by edge intelligence, are now capable of inspecting parts with microscopic precision at full production speeds. These systems use deep learning to identify defects—scratches, cracks, or misalignments—that are invisible to the human eye. By processing this data at the "Edge" (locally on the machine), the robot can take immediate corrective action, such as rejecting a part or pausing the line, before a single defective unit advances to the next stage.

This "Predictive Quality" shift is drastically reducing waste and rework. AI-driven systems analyze historical defect data to uncover root causes, such as a specific tool wearing out or a temperature fluctuation in the facility. In 2026, this data is fed back into the Digital Twin, allowing the factory's AI agent to schedule Predictive Maintenance before a failure even occurs. By turning quality control into a proactive robotic function, manufacturers are achieving "Six Sigma" levels of precision that were previously thought to be impossible in high-speed, high-volume environments.

Sustainable Automation: Green Robotics and Circular Efficiency

Sustainability is a core business priority in 2026, and robotics is a key enabler of "Green Manufacturing." Modern industrial robots are being designed with Energy-Efficient Actuators and "Eco-Modes" that reduce power draw during idle times. Furthermore, the precision of robotics is a major weapon against material waste. By optimizing cutting paths and reducing scrap in additive manufacturing (3D printing), robots ensure that every gram of raw material is used effectively. In 2026, "Circular Robotics" is also on the rise, where robots are used to disassemble old products for recycling and material recovery.

The push for sustainability is also driving the adoption of Digital Product Passports. Every robotic action and material source is logged in a secure ledger, providing total traceability of a product's carbon footprint. Regulators in 2026 are increasingly requiring this level of transparency, and the only way to achieve it at scale is through a fully digitized, roboticized factory. By combining automation with green energy, manufacturers are proving that high-tech production doesn't have to come at the cost of the planet, turning sustainability from a regulatory burden into a competitive advantage.

The Lights-Out Factory: 24/7 Autonomous Shifts

The dream of the "Lights-Out" factory—a facility that runs entirely without human intervention—is becoming a reality for specific shifts in 2026. While a 100% human-free factory remains rare, many operators are now running "Lights-Out Night Shifts." During these hours, robots handle all core workflows—from material picking to packaging—while human supervisors monitor the facility remotely through the industrial metaverse. If a robot encounters a problem it cannot solve, it flags a "remote teleoperation" request, allowing a human to take control of the robot via a VR headset from their home.

This hybrid model allows factories to maximize their ROI by running 24/7 without the need for on-site staffing during antisocial hours. It also provides a "safety valve" for labor shortages. By 2026, the technology to enable these operations—such as "World Models" that give robots common-sense understanding of physics and 5G connectivity for lag-free remote control—has matured. The "Lights-Out" shift represents the ultimate proof of concept for the autonomous factory, demonstrating that when hardware and AI are perfectly synced, the factory can become a self-sustaining engine of productivity.

Conclusion: The Future of the Human Industrial Worker

In conclusion, the transformation of factories through robotics in 2026 is not about the "replacement" of humans, but the amplification of human potential. As robots take over the "3D" jobs—the Dull, Dirty, and Dangerous—human workers are being upskilled into roles focused on strategy, creativity, and system orchestration. The factory worker of 2026 is a "Digital Craftsman" who manages fleets of robots, interprets real-time data, and fine-tunes the AI agents that drive production. This shift is creating a more strategic, adaptive, and safer industrial workforce.

The journey toward the autonomous factory is a journey toward connected intelligence. By embracing Agentic AI, humanoid assistants, and flexible, software-defined systems, manufacturers are building the resilience needed to thrive in a volatile global economy. The robotics revolution is no longer a distant vision; it is a physical reality that is redefining how we build our world. As we look toward 2027 and beyond, the most successful factories will be those that treat technology not as a replacement for people, but as a partner in progress—building a future where humans and machines work side-by-side to create a more prosperous and sustainable world.

References

What manufacturers are automating in 2026 and why (Robotiq) |

8 transformations shaping the future of manufacturing (Manufacturing Today) |

The 6 Defining Manufacturing Trends Of 2026 (Bernard Marr)

Popular posts

-

Random number generatorGenerator tools • 171 views

-

Emojis removerText tools • 168 views

-

Lorem Ipsum generatorGenerator tools • 165 views

-

Reverse lettersText tools • 159 views

-

Old English text generatorText tools • 158 views